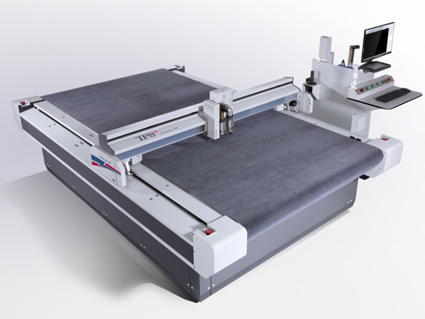

Advantages of Shoe Sample-making machine

To a great extent, shoe sample-making machine can improve the utilization rate of material by setting the safety distance between cardboards in machine software, which saves about 6-8% cardboard.

Shoe sample-making machine is equipped with imported slide, step motor and servo motor, forming an excellent transmitting system and making machine fast, accurate, quieter and stable.

The cutting system is with high efficiency and low costs, can swiftly cut sample, save expenses and time, let products enter market quickly and is also adaptable to the repeated revision of saved sample.

Specifications:

working size: 1600X250mm

Interface and support format:

interface:/serial port/USB/net port

support format: DXF, PLT, AI, PCX, BMP, GIF, PGA, CorelDRAW/AutoCAD

Cost performance:

One machine can replace 4-6 workers.

Cutting material:

Non-mental soft electronic material like pictorial offset plate, ivory board, red cardboard, bonded leather, PVC board, shoe fiber midsole, plastic board shoes, cloth, sticker, double sided tape, PT, PET film, mobile phone film, Copper platinum aluminum platinum, insulating material, heat conduction material etc.

Cutting thickness and speed:

Cutting thickness: ≤2mm

Cutting speed: Max. 2500mm/sec

Fixing methods of material:

Vacuum absorption/electrostatic adherence/double-sided tape

2018-08-13

2018-08-13 admin

admin